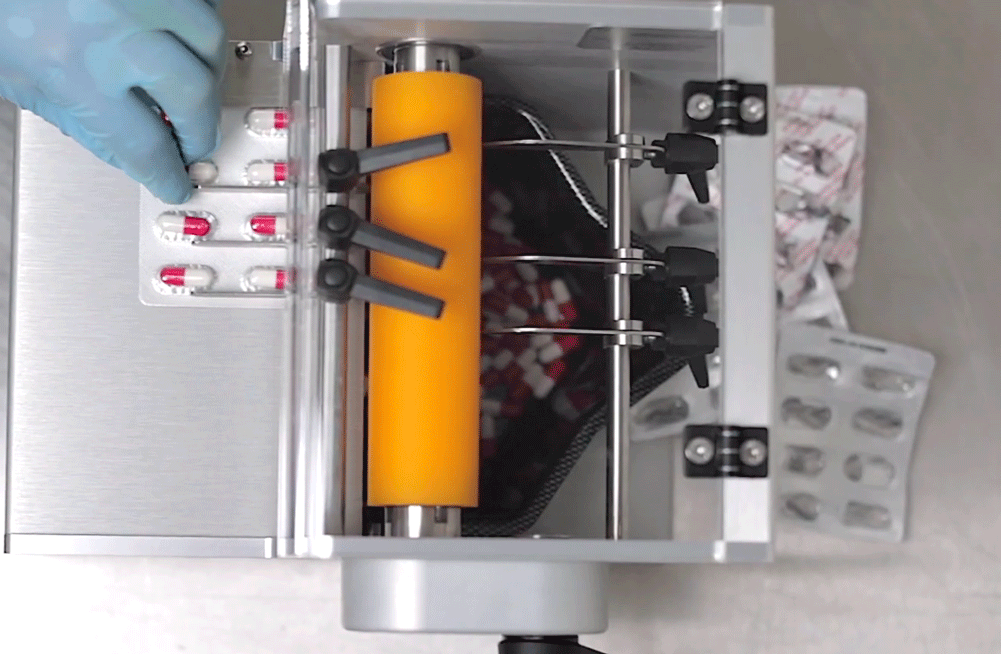

How does the DeBlister Manual Press work.

Pearson Medical Technologies offers the simplest, portable, powerless, and safest deblistering product recovery machine. Its easy to use features make manually deblistering simple and easy. Blister packs are manually fed through the rollers by turning the handle, and tablets or capsules are gently removed from its packaging and separated into a collection drawer without any damage to the pill. The collection tray is easily removed for cleaning to prevent cross contamination from pill dust. The Deblister Manual Press’s non-slip safety pads are fully cGMP compliant and requires no electricity or air supply. This machine does not require additional deblistering tools or changing parts.

Convenient

Portable, single change part. Easy to use. Easily adjusted.

Cleanability

Fully cGMP and easily cleaned

Functionality

Ideal for small batches. Requires no electricity or air supply.

Features of DeBlister Manual Press from Pearson include:

- The DeBlister Manual Unit is capable of deblistering press out blisters at 20 packages per minute.

- DeBlister Manual requires only 1, simple tool change to set and configure for each run.

- The perfect solution to recover small batches of blister packs for returns facilities, pharmacies, packaging facilities, and labs.

- Handles in-line blister packs up to a maximum width of 4.7"/120mm.

- Compact footprint, easily fits on any countertop

- Flexible and easy to use

- Dimensions: 12.6″ x 10.2″ x 8.3″/320mm x 260mm x 210mm

- Also available in a wide model for packages up to 6.7” wide

- Specially designed for push-through blister packs

- Ideal for small batches

- Removable collection tray for easy cleaning and sanitation

- Most affordable solution

- Fully cGMP

- No Power or Air Supply Needed